Brandon’s flagman signals a full stop to the trains behind him

We welcomed fellow enthusiasts from sister clubs Golden Gate & Sacramento to a beautiful spring day run. Not too cool and the AM nor too hot in the PM.

All steaming bays were in use and well managed by Ed and Gerry. Rides were available for all and the tracks were in the best condition we have seen in years.

The new Santa Fe engine “Big Red” was taken on it’s maiden trips around the right of way. Two of the cars have flat-spotted wheels that need to be replaced. The engine seems to want to go fast and may not be a good work engine. Until the air brakes install is completed no more than two passenger cars should be used with this engine as it wants to run downhill.

Photos from Andy from SVLS who we were happy to see return to our tracks.

Mike Masse turned over the beam engine to the club that he has been caring for since John Dolph donated it. Mike has devoted a ton of energy and funds to this project. Evan Bautista will be the new care taker and will train those who want to learn how to safely run the engine.

Here is a summary of what has happened over time under Mike’s care:

The engine runs quiet and smoothly and will pull 3 adults and two kids up to the caboose loop with no power / slippage issues. It can probably handle one more adult or a few more kids but in general Ron’s drop center bench car is a good one-car train for this engine. A lighter car wouldn’t hurt either. I am satisfied with the gear ratio. Water management is super easy, fill it up at the bottom and go all the way to rabbit flat. Fill again and go all the way to caboose. Top up and head down

I trained Evan Bautista on firing up, running and shutting down the engine. I also took photos to assemble a manual. Anyone interested in learning the engine can read the manual first and then have a go at it with someone who already knows how to operate it initially. Evan’s neighbor and new club member Tyler has expressed interest in learning, although he was out of town this month. Matt Petach is also on the short list for next time.

I bought a tool set and oil cans for the engine and made note of a few more things to buy to add to it for next time. I am storing the tools inside the engineer’s car where the propane tanks normally go.

There is a small punch list of items to attend to that I will be working on the next time I come up. The major ones are:

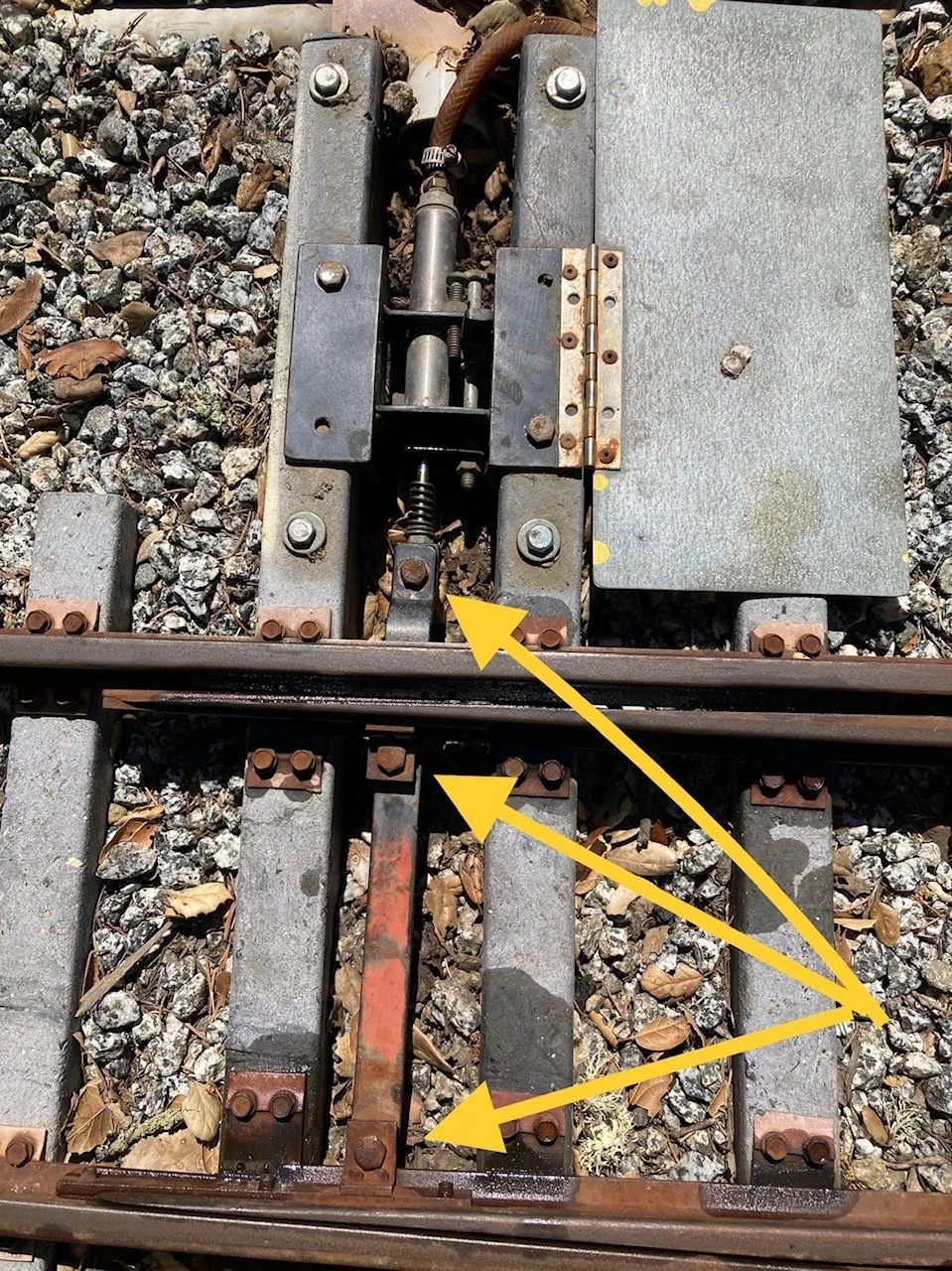

The new springs are too stiff and the front end is still too light. It likes to de-rail at the slightest track defect / twist. I will be experimenting with swapping springs as well as adding weight to the front of the engine. I should be able to do all of this on-site next time. Until then it’s not quite ready for regular operation.

Re-set new safeties to 120 + 125 PSI (currently at 100 + 105)

There are some sleeve bearings at the fulcrums of the beams that like to wiggle their way out after a while. This is an old fix that was forgotten about. I am presently thinking up some retainers to hold them in.

There is a leaky couple of fittings on the brake steam piping and a leaky tee fitting on the throttle that will be fixed on the next outing. Minor leaks but annoying. About an hour of fix time at the steam bays.

The link between the engineer’s car and the engine needs re-working so as to be level, a simple fix involving a longer bolt and lock nut, bringing those next time.

The present manual small-port cylinder cocks are insufficient to avoid a shower even when fully open and left open, I am looking into the possibility of installing superscale steam actuated cylinder cocks and 3-way valve as the most reliable and trouble free solution.